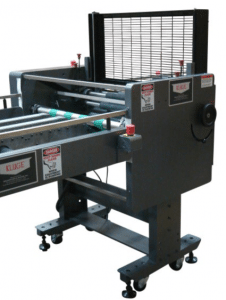

OmniFold 3000 Modular Flexible Packaging Configuration Example

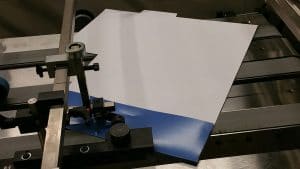

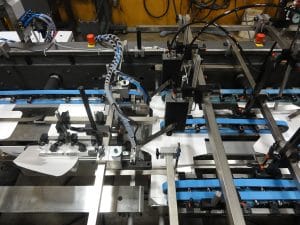

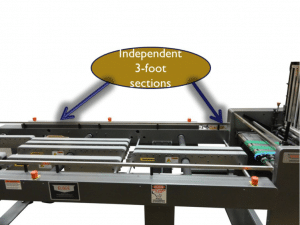

The Open Framework of the OmniFold 3000 means it is easy to set up, easy to run and easy to change over from job to job.

Use it in the morning to run a graphics job, use it in the afternoon to run a packaging job. It’s that simple! Built to maximize converting capabilities while minimizing set-up time, the OmniFold 3000 brings productivity and innovation to a new level.

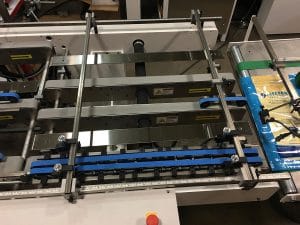

- Compression Stacker – Provides necessary time and compression for successful cold glue applications.

Brandtjen & Kluge is a US manufacturer of quality modular folding and gluing equipment for the graphics, mailing and packaging industries. Kluge multi-function folder gluers are quality-built with versatility in mind.

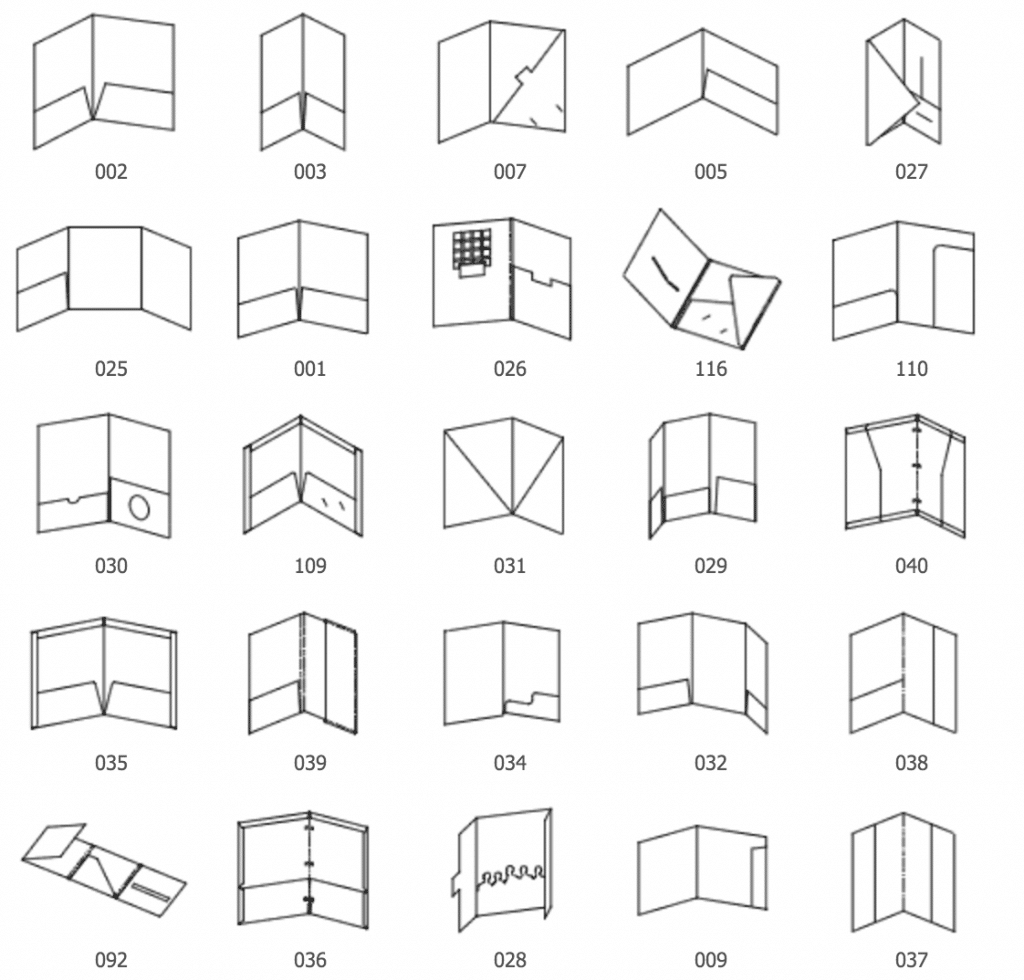

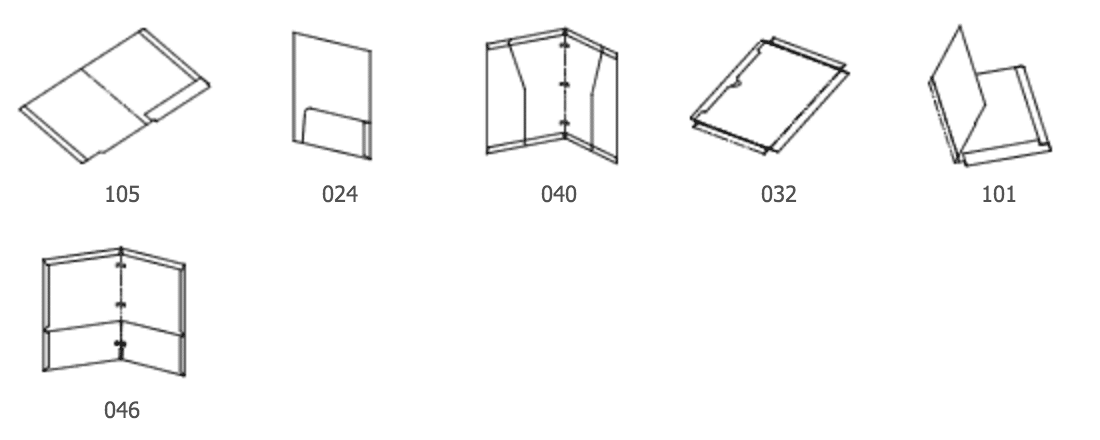

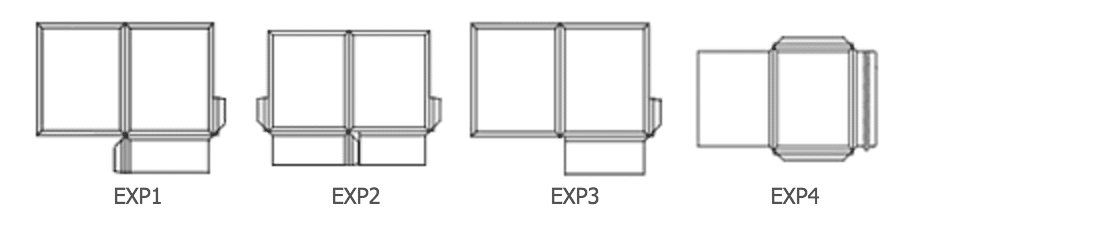

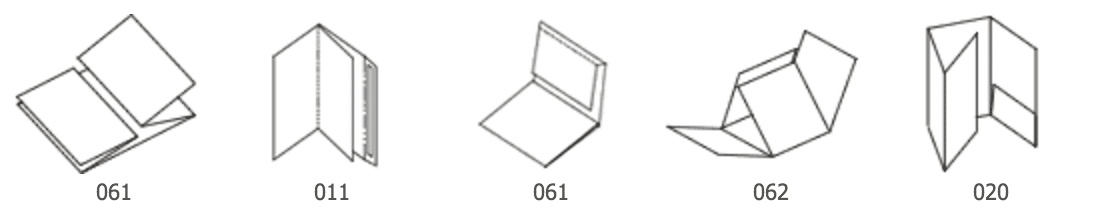

Folding and Gluing. The critical last step in print finishing. Which markets do you serve? Digital Printing? Variable Data Printing? Mailing? Transactional Mailing? Food, Health & Beauty, Pharmaceutical Packaging? Something different? A virtually infinite range of end products can be converted on any one machine. Select your format from the list below for layout drawings, video demonstrations and more details.

Remember, the list below represents only common folder gluer formats, it is not a complete list of the capabilities of our folding and gluing equipment. If you have any questions relating to our line of folder gluers, contact us.

| Specifications | English | Metric |

| Average length (approx.) | 23′- 27′ | 7010 – 8230 mm |

| Width | 72″ | 1830 mm |

| Height | 72″ | 1830 mm |

| Operating Speed | 450 fpm | |

| Maximum Sheet Size | 30″w x 32″ | 762 x 812 mm |

| Minimum Sheet Size | 4″w x 2.5″ | 121 x 96 mm |

| Stock range (coated/uncoated) | .004″ – .030″ | 60 – 660 gsm |

| Electrical | 220-230v, single phase, 50/60 Hz. 40 Amp | |

| Air | 90 psi @ 15 cfm |

The Open Framework of the OmniFold 3000 means it is easy to set up, easy to run and easy to change over from job to job.

Use it in the morning to run a graphics job, use it in the afternoon to run a packaging job. It’s that simple! Built to maximize converting capabilities while minimizing set-up time, the OmniFold 3000 brings productivity and innovation to a new level.