Small Box Folder Gluer

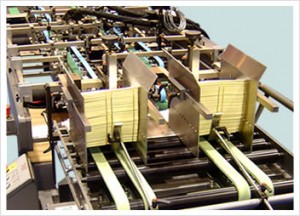

The Kluge Small Box Automatic Folder Gluer provides both productivity and versatility for the high speed production of specialty packaging products. This unique system design addresses the fast growing short to medium run small packaging market.

The Small Box Folder Gluer includes a friction feed unit, TransTable III base unit with small box accessories, Microglue 204 control module and stacker unit as standard.

Easy operation and low entry level cost make the Kluge Small Box Folder Gluer the best solution for meeting the needs of the specialty packaging market.

- 2″ Welded Steel Frame – Stronger than “bolted” frames

- CE Compliance Package

- Friction Feeder Converting Station – For gluing, taping & plow folding

- Electrical Controls – Operate the start, jog and speed controls

- High-end 4 or 8 Channel Controller – Operate a variety of devices

- Narrow Reinforced Folding Sword Attachment – Glue closer to score

- 7″ Plows – Plow folds small partitions. Required for pre-breaking

- 1-RH Small Carton Partition Fold Kit – Plow folds small partitions

- Self Contained Control – For offline transtables and final folds

Brandtjen & Kluge is a US manufacturer of quality modular folding and gluing equipment for the graphics, mailing and packaging industries. Kluge multi-function folder gluers are quality-built with versatility in mind.

Folding and Gluing. The critical last step in print finishing. Which markets do you serve? Digital Printing? Variable Data Printing? Mailing? Transactional Mailing? Food, Health & Beauty, Pharmaceutical Packaging? Something different? A virtually infinite range of end products can be converted on any one machine. Select your format from the list below for layout drawings, video demonstrations and more details.

Remember, the list below represents only common folder gluer formats, it is not a complete list of the capabilities of our folding and gluing equipment. If you have any questions relating to our line of folder gluers, contact us.

| Small Box (32) Folder Gluer | English | Metric |

| Average length (approx.) | 16′ | 488 cm |

| Width | 48″ | 122 cm |

| Height | 38″ | 96.5 cm |

| Maximum sheet size | 28″ x 32″ | 71 x 81 cm |

| Minimum sheet size | 4″ x 2.5″ | 10 x 6.35 cm |

| Operating speed | 4,000 – 40,000 pph, 300 fpm (91 mpm) | |

| Stock Range (coated or uncoated) | .006″ – .024″ | 200 – 500 gsm |

| Total weight (approx.) | 1,500 lbs | 680 kg |

| Shipping weight | 1,900 lbs | 861 kg |

| Electrical | 220V, single-phase, 30 amp |

Download product literature for the Small Box Folder Gluer.

The ComFold is one of Kluge’s automatic multi-function folder gluers. This machine is highly versatile in design and can be easily configured for numerous production formats. The ComFold has in the past, has been referred to as a low cost straight-line folder gluer due to its high speed production for certain applications and multi-function price tag. This video demonstrates why. A playing card box is fed dual stream at 76,000 pph with flawless productivity.

The ComFold is one of Kluge’s automatic multi-function folder gluers. This machine is highly versatile in design and can be easily configured for numerous production formats. The ComFold has in the past, has been referred to as a low cost straight-line folder gluer due to its high speed production for certain applications and multi-function price tag. This video demonstrates why. A playing card box is fed dual stream at 76,000 pph with flawless productivity. The Kluge Friction Feeder was designed to continuously feed stocks that otherwise are difficult or impossible to feed with a Vacuum Feed Unit. The Friction Feeder is portable and is designed to be easily removed when the Vacuum Feed Unit is a better choice to feed a specific stock.

The Kluge Friction Feeder was designed to continuously feed stocks that otherwise are difficult or impossible to feed with a Vacuum Feed Unit. The Friction Feeder is portable and is designed to be easily removed when the Vacuum Feed Unit is a better choice to feed a specific stock. Like the bucklefolder, the airgate folding kit creates cross folds. However, this feature does not use rollers to convert your product. Instead the airgate uses an air blast from below the machine to push the stock upwards at the correct point in the converting process. The Airgate is used to fold thick stocks or to create cross folds in addition to the bucklefolder, giving a machine greater converting capabilities.

Like the bucklefolder, the airgate folding kit creates cross folds. However, this feature does not use rollers to convert your product. Instead the airgate uses an air blast from below the machine to push the stock upwards at the correct point in the converting process. The Airgate is used to fold thick stocks or to create cross folds in addition to the bucklefolder, giving a machine greater converting capabilities. The Bump 90 attachment rotates the sheet 90 degrees inline, providing accurate alignment for plow folding, taping and two directional gluing.

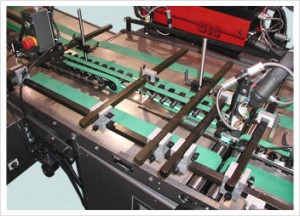

The Bump 90 attachment rotates the sheet 90 degrees inline, providing accurate alignment for plow folding, taping and two directional gluing. Delivers continuous drive and pressure to products. The continuous drive aspect improves sheet control to all products that require plow, airgate or flipgate folding. Utilizes 1/8″ thick belt with skew adjustment for fine tuning sheet alignment. The Top Belt Drives have independently spring loaded pressure wheels to maintain even and firm pressure with sealed bearings throughout.

Delivers continuous drive and pressure to products. The continuous drive aspect improves sheet control to all products that require plow, airgate or flipgate folding. Utilizes 1/8″ thick belt with skew adjustment for fine tuning sheet alignment. The Top Belt Drives have independently spring loaded pressure wheels to maintain even and firm pressure with sealed bearings throughout. Kluge folder gluers can be configured with several different types of glue systems for hot melt gluing, cold glue or fugitive gluing. Depending on your application and control module, several glue heads can be used simultaneously which include a range of melt or stainless steel tanks.

Kluge folder gluers can be configured with several different types of glue systems for hot melt gluing, cold glue or fugitive gluing. Depending on your application and control module, several glue heads can be used simultaneously which include a range of melt or stainless steel tanks. In keeping with our reputation for highly versatile equipment, we have manufactured a fold hook kit for our automatic folder gluers. The optional feature enables users to convert auto-lock bottom boxes and comparable products inline, and at speeds of up to 5,000 + pieces per hour.

In keeping with our reputation for highly versatile equipment, we have manufactured a fold hook kit for our automatic folder gluers. The optional feature enables users to convert auto-lock bottom boxes and comparable products inline, and at speeds of up to 5,000 + pieces per hour. The Kluge Small Carton TransTable III Converting Unit adds versatility to your folder gluer. The unit comprises of two converting stations. These 3-foot long conveyor-like tables features four 2-1/2″ wide belts and can be configured for gluing, taping, plow folding, airgate folding and bump 90.

The Kluge Small Carton TransTable III Converting Unit adds versatility to your folder gluer. The unit comprises of two converting stations. These 3-foot long conveyor-like tables features four 2-1/2″ wide belts and can be configured for gluing, taping, plow folding, airgate folding and bump 90. Also known as the ‘Pick and Place Unit’, the optional Inserter for Kluge folder gluers allow for placement of an item inline with folding and gluing. In this demonstration a friction-fed tipping unit is mounted to our ComFold folder gluer to onsert CD media onto a flat single pocket CD sleeve. The sleeve is then folded and glued around the CD using hot melt glue and our flip gate feature.

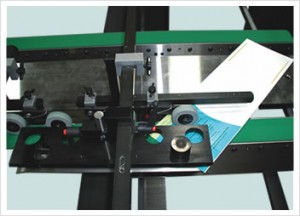

Also known as the ‘Pick and Place Unit’, the optional Inserter for Kluge folder gluers allow for placement of an item inline with folding and gluing. In this demonstration a friction-fed tipping unit is mounted to our ComFold folder gluer to onsert CD media onto a flat single pocket CD sleeve. The sleeve is then folded and glued around the CD using hot melt glue and our flip gate feature. Applying self-adhesive transfer tape or reinforcement tape in-line is easy with the automatic tape head. The tape head can be attached to the converting station in the feeding section or either converting station on the TransTable Unit. The tape head is designed to operate with the standard control module.

Applying self-adhesive transfer tape or reinforcement tape in-line is easy with the automatic tape head. The tape head can be attached to the converting station in the feeding section or either converting station on the TransTable Unit. The tape head is designed to operate with the standard control module. Stacking and batching is made easy with the Kluge Stacker Unit. An electronic batch counter controls the belt drive providing consistent batching. An electronic totalizing counter keeps track of total production. The stacker height is easily adjusted by a rack-and-pinion drive.

Stacking and batching is made easy with the Kluge Stacker Unit. An electronic batch counter controls the belt drive providing consistent batching. An electronic totalizing counter keeps track of total production. The stacker height is easily adjusted by a rack-and-pinion drive.