As the premier manufacturer of Foil Stamping, Embossing and Die-Cutting Automatic Platen Presses, Kluge understands that the two most important considerations when purchasing any piece of equipment are: Performance and Economy.

As the premier manufacturer of Foil Stamping, Embossing and Die-Cutting Automatic Platen Presses, Kluge understands that the two most important considerations when purchasing any piece of equipment are: Performance and Economy.

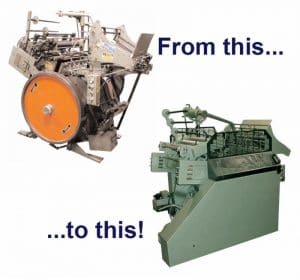

We hold a strong reputation for excellence in providing high-quality, Remanufactured Kluge EHD and EHF Automatic Platen Presses that are reasonably priced. These presses have passed the same rigorous quality control testing that our new Kluge equipment goes through.

The Benefits of a Remanufactured Platen Press over Used Equipment:

- All new and Remanufactured Kluge Platen Presses come with an owner’s manual and a parts manual.

- A new Kluge Platen Press has a one year warranty on parts and a Remanufactured Kluge Platen Press has a 6 month warranty on parts.

- Kluge maintains a complete inventory of parts for all presses that are currently manufactured. (For product liability reasons we do not sell parts to machines manufactured before 1960.)

- The purchase of a new or Remanufactured Kluge includes installation. Additional operator training is also available.

- All Kluge Platen Presses, new or Remanufactured, are guarded to meet current OSHA and ANSI standards.

- Kluge welcomes visitors to see a press prior to shipment. We will be happy to demonstrate the press for you or send you samples of work produced on the press.

Here’s what users are saying about their Remanufactured Kluge Automatic Platen Press:

It’s easy to see why most finishing shops have at least one Kluge. The versatility and ease of use makes it a true work horse. – JohnHenry Ruggieri, SunDance

Kluge offers a superior product for its market and KC [Kluge’s product design and technical support manager] did an excellent job training our operators and getting Linemark ready for profitable production. We’re making money with our Kluge. – Steve Bearden, Linemark

Read: Linemark is Making Money With the Addition of a Kluge EHD Automatic Platen Press

We have used Kluge equipment for over 15 years to make all those ‘extra’ features happen. Four operators run and maintain two Kluge presses along with a Kluge UniFold folder-gluer and a Heidelberg Windmill. The addition of a third Kluge press in January has allowed us increased output, flexibility and machine dependability, as we add those extras to our product. The purchase of a remanufactured machine was an easy decision knowing Kluge’s proven value. – Mike Bognar, Leanin’ Tree

Read: Leanin’ Tree Installs a Kluge EHD to Increase Output, Flexibility and Dependability

During the Kluge EHD demonstration at Drupa 2016, it became totally compelling for us to invest in this machine based on its versatility and the quality of product it could produce. Even though it would still require a skilled operator, it was clearly the purchase to make as quality is something on which we will not compromise. The addition of the Kluge has not only allowed supplementary processes such as the embossing of thick board, but because of the extra impression pressure available, it has had a positive effect on the end quality of the product. – Charlie Anderson, C&D Print Media

We believe that technology and the right equipment is key to the continued success of YPS and we have made a number of key purchases recently. We first came across Kluge at Drupa 2016 when we were seeking out die-cutting and foiling options. Having not previously been familiar with their products, we were very impressed with the foiling and embossing on the Kluge, which was far superior to anything we had seen before. The Kluge adds perfectly to our internal finishing capabilities and will allow us to both foil and die-cut in-house, thereby keeping control of time critical jobs. – Steve Brown, Your Print Solution