EHD Series (14 x 22)

Often called “the workhorse of the industry”, the Kluge EHD is already a legend. Featuring speeds up to 3,300 impressions per hour, the EHD now comes with delayed delivery allowing it to accommodate sheets up to 17″x 24.75″ (431mm x 628mm), with up to 40 square inches of die area. Kluge’s patented Delayed Dwell technology allows the EHD to start on impression sooner, bottom out, and remain on impression longer doubling impression time with no loss of production speed and assuring flawless foil separation from the stock. A new, optional, freestanding mobile electronics console puts all press operations in one place for easy access. The same console can also serve as a workstation and toolbox.

Rugged, dependable and simple to operate, the EHD is known for providing years of reliable service in foil stamping, embossing and die cutting, and for over 25 years has been the standard by which all presses in its class are measured.

All Kluge presses can be supplied with the electrical specification of your country.

Standard

- With vacuum operated feed arm for smooth feeding of a wide range of stock types and thicknesses

- Delayed Delivery – Allows stock greater than 14″ to be run on the EHD

- Micro Adjustable Gauge Band – Precisely adjust the gauge band for sheet placement

- Feed Without Impression Control – Allows setup of feed and delivery without risking valuable dies and wasting expensive foil

- Impression counter – Will only count the number of impressins for easy totalling of completed stock

- Rotary Vacuum Pump – Allows independent control of the delivery vacuum

- Auto Lubrication System – Provides hands off worry free lubrication of critical press bearings

- Three-Nozzle Air Blast Foil Release – Separates foil web from the stock for improved product quality and increased productivity (requires separate compressor or air system)

- Complete Guarding with Electric Interlock System – Meets rigorous safety standards yet provides access to press

Options

- Variable Speed Control – Control press speed with greater accuracy

- Filler Plate – Replacement for die heating plate when die cutting

- Missed Sheet Detector – Prevents die, make-ready and press damage

- Foil Detector – Stops the press when a roll of foil is empty

- Greeting Cards

- Letterheads/Stationary

- Holograms

- Announcements

- Pocket Folders

- Report Covers

- Paperback/Case bound Book Covers

- Security Printing

- Labels

- Packaging

- Business Cards

- Die Cutting/Kiss Cutting

| EHD Series | English | Metric |

| Platen size | 14″ x 22″ | 356 x 559 mm |

| Minimum sheet size | 4″ x 5″ | 102 x 127 mm |

| Maximum sheet size* | 17″ x 24.75″ | 431 x 628 mm |

| Magazine Capacity | 14″” | 356 mm |

| Delivery Capacity | 14″ | 356 mm |

| Air | 90 psi @ 10cfm | |

| Stock range | Onion Skin to .200″ board | |

| Inside Chase Dimensions | 14″ x 22″ | 356 x 559 mm |

| Outside Chase Dimensions | 16.25″ x 23.5″ | 413 x 597 mm |

| Main and Back Shaft Diameter | 4.375″ | 111 mm |

| Maximum operating speed | 3,300 iph | |

| Machine power required | 3 h.p., A.C. 230/460 volt, 3 phase, 1800 rpm, 60 cycle | |

| Machine dimensions | 74″ x 50″ x 68″ | 1880 x 1270 x 1727 mm |

| Net weight (approx.) | 4400 lbs | 1996 kg |

| Total weight (approx.) | 5000 lbs | 2268 kg |

*Delayed Delivery is now standard on new EHD presses allowing for sheet sizes greater than 14″. The optional Wide Magazine upgrade increases the maximum sheet width to 26.25″.

Download product literature for the EHD Series Press.

EHD and EHF Series brochure (820kb)

EHD & EHF Series Press Rebuild Program

EHD Series Press Safety Upgrade Booklet

FSEA – The Designer’s Guide to Foil Stamping & Embossing

The User’s Guide to Hologram Stamping

Stages in the Make-Ready Process – Reference Guide (1.5mb)

Embossing and Foil Stamping: Techniques Made Easy – Reference Guide (2.8mb)

What’s the Difference Between an EHD and an EHF?

In general, the Kluge EHF Series Press has many more standard features than the EHD Series. This gives the EHF greater and more efficient foil stamping, embossing & die cutting capabilities on both short and long run print jobs.

The table below provides an overview of the differences between the EHD and EHF Presses.

Contact Kluge for further information on these presses.

| Feature | EHD | EHF | ||

| Standard | Option | Standard | Option | |

| Wide Magazine | X | X | ||

| Pre-load Magazine | X | X | ||

| Delayed Delivery | X | X | ||

| Two-up Feeding | X | X | ||

| Missed Sheet Detector | X | X | ||

| Filler Plate | X | X | ||

| Micro-Adjustable Bottom Gauge Band | X | X | ||

| Mechanical Jogger | X | X | ||

| Variable Speed Control | X | X | ||

| Electronic Foil Control System | X | X | ||

| Dual Foil Rewind | X | N/A | N/A | |

| Foil Detector | X | X | ||

| Hologram Registration | X | X | ||

| Grid Etched Lightweight Toggle Base | X | X | ||

| Overdrive | X | X | ||

| Adjustable Impression | X | X | ||

| Lockout Delayed Dwell system | X | X | ||

| Reversible Register Cam | X | X |

The press comes equipped with a three-draw mechanical foil control system (MFCS) as standard. This configuration allows for a wide array of foil draw and coverage with highly accurate registration between images. All Kluge foil control systems utilize an air blast system to assure the foil relay from stock between impression.

The press comes equipped with a three-draw mechanical foil control system (MFCS) as standard. This configuration allows for a wide array of foil draw and coverage with highly accurate registration between images. All Kluge foil control systems utilize an air blast system to assure the foil relay from stock between impression. The Kluge delivery system utilizes a four-finger delivery arm operating on a straight-out motion. Combined with a receding pile delivery table and impression counter, the Kluge EHD will not mar stock and gives the operator accurate press usage.

The Kluge delivery system utilizes a four-finger delivery arm operating on a straight-out motion. Combined with a receding pile delivery table and impression counter, the Kluge EHD will not mar stock and gives the operator accurate press usage. Today the hologram has a whole range of uses from security tags to packaging, book covers and advertising. The video here demonstrates registering a hologram as part of a seven pass colorful foil/hologram display card. Read on to learn more about Kluge’s hologram registration technology and capabilities.The Kluge Hologram Registration Unit is built onto the Electronic Foil Control System, Low Mount. It enables you to accurately register holograms using your Kluge press. Note: the hologram registration unit is not compatible with the mechanical foil control system.

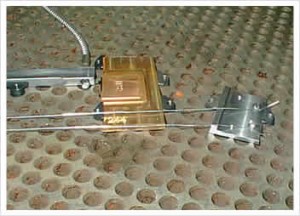

Today the hologram has a whole range of uses from security tags to packaging, book covers and advertising. The video here demonstrates registering a hologram as part of a seven pass colorful foil/hologram display card. Read on to learn more about Kluge’s hologram registration technology and capabilities.The Kluge Hologram Registration Unit is built onto the Electronic Foil Control System, Low Mount. It enables you to accurately register holograms using your Kluge press. Note: the hologram registration unit is not compatible with the mechanical foil control system. The Hologram Registration Unit utilizes fiber optic technology as the hologram registration mark detection system. The fiber optic sensor is mounted to the toggle base in line with the edge of the foil. The sensor is connected to the signal pick up device, also known as the ‘amplifier’ which is then electronically adjusted until the registration mark can be seen. This innovative system allows you to digitally align hologram foil on the die with registration accuracy of +/- .012″.

The Hologram Registration Unit utilizes fiber optic technology as the hologram registration mark detection system. The fiber optic sensor is mounted to the toggle base in line with the edge of the foil. The sensor is connected to the signal pick up device, also known as the ‘amplifier’ which is then electronically adjusted until the registration mark can be seen. This innovative system allows you to digitally align hologram foil on the die with registration accuracy of +/- .012″. Two #30 gauge wire guides are positioned on the toggle base just below the die, one is placed under the foil and the other is placed over the foil. These wire guides effectively prevent the hologram foil from curling as it is fed through the machine (see photo).Easy access to the configuration and controls of the Hologram Registration Unit is made available from the touch screen control system.Kluge has developed a “User Guide to Hologram Stamping”. Click here to download your free copy and learn about everything from history, to foil types to the technology involved in producing quality holograms.

Two #30 gauge wire guides are positioned on the toggle base just below the die, one is placed under the foil and the other is placed over the foil. These wire guides effectively prevent the hologram foil from curling as it is fed through the machine (see photo).Easy access to the configuration and controls of the Hologram Registration Unit is made available from the touch screen control system.Kluge has developed a “User Guide to Hologram Stamping”. Click here to download your free copy and learn about everything from history, to foil types to the technology involved in producing quality holograms. Until now, adjusting the platen bolts and/or adding packing behind the make-ready plate has been the make-ready process for impression adjustments on Kluge presses. Adjustments to the platen bolts are cumbersome and time consuming. Each bolt has to be adjusted equally to maintain as close to level as possible. Because of the inherent design, when raising the platen to increase pressure the platen is put out of parallel with the bed slightly creating more pressure toward the bottom of the platen.

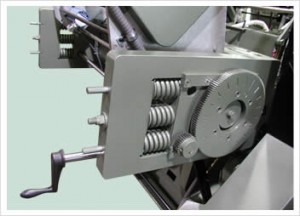

Until now, adjusting the platen bolts and/or adding packing behind the make-ready plate has been the make-ready process for impression adjustments on Kluge presses. Adjustments to the platen bolts are cumbersome and time consuming. Each bolt has to be adjusted equally to maintain as close to level as possible. Because of the inherent design, when raising the platen to increase pressure the platen is put out of parallel with the bed slightly creating more pressure toward the bottom of the platen. The preload magazine allows you to reload the press with new stock while the press is running, therefore less down time and higher production speeds. Perfect for long runs such as greeting cards or book covers.

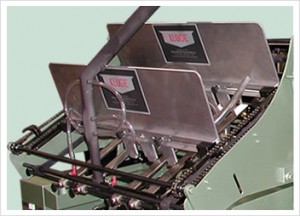

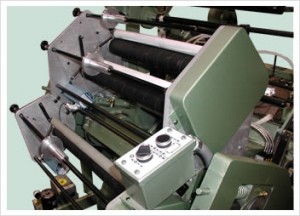

The preload magazine allows you to reload the press with new stock while the press is running, therefore less down time and higher production speeds. Perfect for long runs such as greeting cards or book covers. Designed to be even more operator-friendly by making the foil unwind and rewind shafts more accessible to the operator.

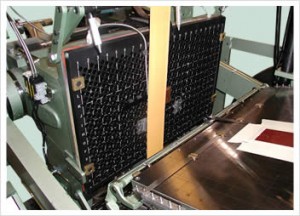

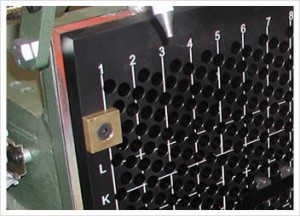

Designed to be even more operator-friendly by making the foil unwind and rewind shafts more accessible to the operator. The lightweight grid-etched toggle base enables the operator to quickly and accurately align the die(s) on the toggle base during make-ready. The laser-etched grid is labelled numerically on the horizontal axis, and alphabetically on the vertical axis. The grid is replicated on the platen.

The lightweight grid-etched toggle base enables the operator to quickly and accurately align the die(s) on the toggle base during make-ready. The laser-etched grid is labelled numerically on the horizontal axis, and alphabetically on the vertical axis. The grid is replicated on the platen.